Club

Traffic Light II

Intersection Control and Communication Systems

Traffic Light II

Intersection Control and Communication Systems

GENERAL INTRODUCTION FOR TRAFFIC CONTROLLERS

Intersection traffic signals are usually controlled by a computerized control system located in a locked cabinet at the intersection. Inside the cabinet houses all the control equipment necessary to control the intersections signals timing and programs, the phase structures, and any inputs such as detection. The National Electrical Manufacturers Association, or NEMA, standardizes most manufacturers controllers so that equipment can be used interchangeably. Older controllers prior to the development of the computerized ones were mechanically driven with solenoids and cams.

"NEMA TS-1" versus "NEMA TS-2"

NEMA Traffic Signal Controller Assemblies are divided into two Technical Specifications (TS): TS-1 and TS-2.

TS-1 was developed in the 1970s and is the most common standard when one thinks of NEMA controllers. Large A, B, C cables run from the controller directly to the backpanel, all the individual circuits are directly inputted into the backpanel. There is no communication, circuits operate with a simple ON/OFF logic based on the controller programming.

TS-2 was developed in 1992 and replaced the A/B/C connectors with high speed data bus, or SDLC line. Information is sent, recieved, and replied to 100 times a second between all the equipment. Theres a wider flexiblity with TS2, as the circuits are not direct connections to the backpanel.

TS-2 is often broken down into TS-2 Type 1 and TS-2 Type 2. In TS2 Type 1, the entire cabinet runs the TS-2 communication system, TS-2 Type 2 only runs the communication for the monitor and detectors...the backpanel uses the A/B/C connections like TS-1.

TS-1 was developed in the 1970s and is the most common standard when one thinks of NEMA controllers. Large A, B, C cables run from the controller directly to the backpanel, all the individual circuits are directly inputted into the backpanel. There is no communication, circuits operate with a simple ON/OFF logic based on the controller programming.

TS-2 was developed in 1992 and replaced the A/B/C connectors with high speed data bus, or SDLC line. Information is sent, recieved, and replied to 100 times a second between all the equipment. Theres a wider flexiblity with TS2, as the circuits are not direct connections to the backpanel.

TS-2 is often broken down into TS-2 Type 1 and TS-2 Type 2. In TS2 Type 1, the entire cabinet runs the TS-2 communication system, TS-2 Type 2 only runs the communication for the monitor and detectors...the backpanel uses the A/B/C connections like TS-1.

CABINET COMPONENTS OVERVIEW

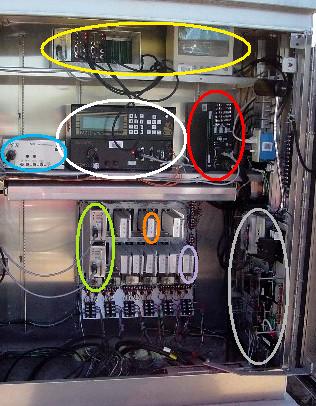

The colors of the highlight cabinet component will correspond to the color of the text.

THE CONTROLLER: This is the central processing unit for all intersection functions. This unit inputs data from sources such as detection or a master unit and, through its programming, outputs information to the signal heads. This particular controller is designed to only be used in TS2 cabinets, note the small power connector and no A, B, C, ports.

MMU: This device is the Malfunction Management Unit or Conflict Monitor in older cabinets. It's job is to monitor for failures in cabinet wiring, damage to components, loss of voltages, or conflicting displays on the signal heads. If any such failure is found the monitor will transfer power to the flasher and the controller will cease running the signals.

The difference between the older "conflict monitor" and the newer "MMU" is that MMU's provide a communication link between the components of a TS2 system. Conflict Monitors are used primarily in a TS1 system. The one pictured is an MMU.

POWER SUPPLY: This device allows for multiple voltages to run in a TS2 cabinet. It outputs the standard 24 volts, plus 12 volts, and 5 volts for logic circuits.

VIDEO PROCESSOR/RACK: This is the interface between the video detection cameras and the controller. The detection is picked up by the software in the rack mounted cards to the left. The unit on the right is a monitor picking up real-time information of vehicle activity through the cameras. The detection zones are marked on the monitor screen. The monitor is used to check the aim of the camera and when vehicles pass through the camera's detection zones.

BIU: The Buss Interface Unit or BIU interfaces the communication between the terminal facility (or Backpanel) and the controller in a TS2 cabinet. Because TS2 uses SDLC communication, the BIU interfaces the information sent from that port to run the load switches and various other components.

LOAD SWITCH: The load switch is a device that converts the low voltage information from the controller to high voltage power that directly changes the signal head lamps. Load switches often have high-power ratings to allow for multiple high-wattage signals to be connected to a single channel. The load switch, simply put, acts like a electronic relay between the signal lamps and controller. All power leaving the load switch outputs are checked by the MMU to make sure there is no faults in the device.

FLASHER: The flasher looks similar to a load switch but only has two status LEDs, as opposed to the Load Switch's three LEDs. When power is applied to the flasher the two outputs alternate flash at a standard rate of 56 Flashes per Minute. A flasher has many uses, one of which is to control the intersection during a controller failure. Power is transferred to the flasher via a series of transfer relays in the event the MMU (or Conflict Monitor) picks up a fault. In older cabinets the flasher provided "Night Flash" Most controllers now have that built in to their programming.

POWER PANEL: The power panel contains all the breakers and other various electrical components to step down power to the cabinet. Power panels may also contain standard 120 volt outlets for various uses

THE CONTROLLER: This is the central processing unit for all intersection functions. This unit inputs data from sources such as detection or a master unit and, through its programming, outputs information to the signal heads. This particular controller is designed to only be used in TS2 cabinets, note the small power connector and no A, B, C, ports.

MMU: This device is the Malfunction Management Unit or Conflict Monitor in older cabinets. It's job is to monitor for failures in cabinet wiring, damage to components, loss of voltages, or conflicting displays on the signal heads. If any such failure is found the monitor will transfer power to the flasher and the controller will cease running the signals.

The difference between the older "conflict monitor" and the newer "MMU" is that MMU's provide a communication link between the components of a TS2 system. Conflict Monitors are used primarily in a TS1 system. The one pictured is an MMU.

POWER SUPPLY: This device allows for multiple voltages to run in a TS2 cabinet. It outputs the standard 24 volts, plus 12 volts, and 5 volts for logic circuits.

VIDEO PROCESSOR/RACK: This is the interface between the video detection cameras and the controller. The detection is picked up by the software in the rack mounted cards to the left. The unit on the right is a monitor picking up real-time information of vehicle activity through the cameras. The detection zones are marked on the monitor screen. The monitor is used to check the aim of the camera and when vehicles pass through the camera's detection zones.

BIU: The Buss Interface Unit or BIU interfaces the communication between the terminal facility (or Backpanel) and the controller in a TS2 cabinet. Because TS2 uses SDLC communication, the BIU interfaces the information sent from that port to run the load switches and various other components.

LOAD SWITCH: The load switch is a device that converts the low voltage information from the controller to high voltage power that directly changes the signal head lamps. Load switches often have high-power ratings to allow for multiple high-wattage signals to be connected to a single channel. The load switch, simply put, acts like a electronic relay between the signal lamps and controller. All power leaving the load switch outputs are checked by the MMU to make sure there is no faults in the device.

FLASHER: The flasher looks similar to a load switch but only has two status LEDs, as opposed to the Load Switch's three LEDs. When power is applied to the flasher the two outputs alternate flash at a standard rate of 56 Flashes per Minute. A flasher has many uses, one of which is to control the intersection during a controller failure. Power is transferred to the flasher via a series of transfer relays in the event the MMU (or Conflict Monitor) picks up a fault. In older cabinets the flasher provided "Night Flash" Most controllers now have that built in to their programming.

POWER PANEL: The power panel contains all the breakers and other various electrical components to step down power to the cabinet. Power panels may also contain standard 120 volt outlets for various uses

MASTER/LOCAL (CLOSED LOOP) SYSTEMS

Most controllers operating today involve a master/local communication system. While controller's of the past were isolated, today's units are interconnected with eachother to provide coordination or off-site programming and upgrading. An intersection usually is equipped with a single local controller cabinet. Information is sent back and forth to an off-site master controller, sometimes located in a larger intersection cabinet with the local of that particular intersection, called an "On-Street Master". The cabinet's that house both the master for the communicating intersections and the local for the specific intersection being controlled are usually "coordinating hubs" for the area's coordination system. Some Masters are remotely connected, sometimes within the traffic signal department for the city or state. Remote and Off-site masters can be programmed via the controller's keypad and screen or downloaded via PC. The master's job is to communicate with all it's interconnected local controllers providing coordination among it's intersections. A master can ease programming since each local intersection can be pulled up on the master, reprogrammed and downloaded to its respective intersection. When coordination changes, programming done through the master is downloaded to the local intersection cabinets changing the coordination plans for each intersection down the line.

Not all controllers are NEMA certified. Type 170 (One-Seventy) controllers, for example, contain the same components as a NEMA cabinet but are arranged in a more modular format, like a computer server. 170 controllers allow for much more programming capabilities by simply inserting a new software card into the CPU.

Type 2070 (Twenty-Seventy) controllers are similar to 170s, yet can be installed in both a 170 cabinet and a NEMA cabinet. 2070s are normally more menu driven whereas 170 was code based.

Mechanical controllers are the earliest automatic traffic signal controllers. They come in a variety of types depending on the manufacturer but the basic principle on their operation is the same....a dial turns slowly with keys notched in it, each time a key hits a switch on the cycle unit, it energizes a solenoid which turns a cam drum. The drum has contacts for all the lights at the intersection, and wherever a cam on the drum is broken away a contact closes and the light comes on. Simple technology that is still seeing service in many places.

Type 2070 (Twenty-Seventy) controllers are similar to 170s, yet can be installed in both a 170 cabinet and a NEMA cabinet. 2070s are normally more menu driven whereas 170 was code based.

Mechanical controllers are the earliest automatic traffic signal controllers. They come in a variety of types depending on the manufacturer but the basic principle on their operation is the same....a dial turns slowly with keys notched in it, each time a key hits a switch on the cycle unit, it energizes a solenoid which turns a cam drum. The drum has contacts for all the lights at the intersection, and wherever a cam on the drum is broken away a contact closes and the light comes on. Simple technology that is still seeing service in many places.

OTHER CONTROLLERS: 170, 2070, and Mechanical