Club

Traffic Light II

Traffic Signal Design

Traffic Light II

Traffic Signal Design

TRAFFIC SIGNAL DESIGN

A traffic signal head is the visual display component of the signal system. Its constructed of individual sections that is assembled to form a signal head. A typical signal is constructed out of three sections.

The body is known as the "housing" The housing is normally made of polycarbonate plastic, with older signals constructed of aluminum. The housing contains all the optics and wiring for the signal head.

The "lens door" is installed on the front of the housing and secured to the signal with latches and wing nuts, typically. The lens door supports the "lens", which is usually made of either heavy glass or tough polycarbonate, and the "visor" which surrounds each lens protecting it from weather and the sun glare. Visors are made, usually, out of the same material as the housing.

The internal optics of the signal can vary but most notably, Incandescent or LED optics are used.

Incandescent signal assemblies utilize a metallic reflector that is mounted to an aluminum frame installed in the signal housing. A standard traffic lamp is installed in the center of the reflector, which is a medium base, clear glass, lamp, ranging from 40W to 169W depending on the lamp. In an 8 inch signal display or for pedestrian signals, 69W is common. 116W is usually common for 12 inch signals. The socket mounts to the reflector by means of a thin wire stretching across the backside of the reflector assembly. This is the "bail"

The reflector and lens, when the lens door is closed, form a sealed dust-free unit.

In an LED Signal, much of the optics are removed. An sealed LED fixture, made usually by an independent manufacturer outside the signal head manufacturer, mounts to the door in the same way a standard lens is. LED signals drop the wattage down to around 10W, last nearly forever, and don't produce any heat that would distort the lens over time. LED signals are becoming more common than incandescent with some municipalities.

The wiring from either the socket or the LED assembly from each section are met up at the signals "connection block" in one of the housings. The connection block contains screw terminals so that signal head wires can interconnect with the field wires leading to a controller cabinet.

The body is known as the "housing" The housing is normally made of polycarbonate plastic, with older signals constructed of aluminum. The housing contains all the optics and wiring for the signal head.

The "lens door" is installed on the front of the housing and secured to the signal with latches and wing nuts, typically. The lens door supports the "lens", which is usually made of either heavy glass or tough polycarbonate, and the "visor" which surrounds each lens protecting it from weather and the sun glare. Visors are made, usually, out of the same material as the housing.

The internal optics of the signal can vary but most notably, Incandescent or LED optics are used.

Incandescent signal assemblies utilize a metallic reflector that is mounted to an aluminum frame installed in the signal housing. A standard traffic lamp is installed in the center of the reflector, which is a medium base, clear glass, lamp, ranging from 40W to 169W depending on the lamp. In an 8 inch signal display or for pedestrian signals, 69W is common. 116W is usually common for 12 inch signals. The socket mounts to the reflector by means of a thin wire stretching across the backside of the reflector assembly. This is the "bail"

The reflector and lens, when the lens door is closed, form a sealed dust-free unit.

In an LED Signal, much of the optics are removed. An sealed LED fixture, made usually by an independent manufacturer outside the signal head manufacturer, mounts to the door in the same way a standard lens is. LED signals drop the wattage down to around 10W, last nearly forever, and don't produce any heat that would distort the lens over time. LED signals are becoming more common than incandescent with some municipalities.

The wiring from either the socket or the LED assembly from each section are met up at the signals "connection block" in one of the housings. The connection block contains screw terminals so that signal head wires can interconnect with the field wires leading to a controller cabinet.

GENERAL OVERVIEW OF TRAFFIC SIGNAL MANUFACTURING

Traffic signals are usually manufactured using the same, or similar process. The only difference is the materials being used.

With aluminum signals, molten aluminum is poured into a die cast machine. The machine rams the molten metal with a hydraulic arm into a two halve mold that closes tightly. When the part is hardened and cooled enough it is ejected. The aluminum housing usually has alot of excess metal on it. The part is trimmed using either a stamping die or by hand.

Visors are rolled to their shape out of pre-cut aluminum sheets. All aluminum parts are washed prior to being powdercoated.

All external aluminum parts are powdercoated, a process of baking paint onto the metal in an industrial oven. Reflectors are spun from aluminum

The signal head itself is normally assembled by hand.

Polycarbonate signals are made similarly, but use an injection molding machine for the manufacture of the door, housing, visor, or lens parts. Plastic pellets are melted down in an injection machine. A screw then turns forcing the melted plastic into the mold. When the part cools it ejects and the sprues are trimmed off. Noticable marks from the screw injector on polycarbonate parts are on the back center of each section, and on the front center of most poly lenses.

With aluminum signals, molten aluminum is poured into a die cast machine. The machine rams the molten metal with a hydraulic arm into a two halve mold that closes tightly. When the part is hardened and cooled enough it is ejected. The aluminum housing usually has alot of excess metal on it. The part is trimmed using either a stamping die or by hand.

Visors are rolled to their shape out of pre-cut aluminum sheets. All aluminum parts are washed prior to being powdercoated.

All external aluminum parts are powdercoated, a process of baking paint onto the metal in an industrial oven. Reflectors are spun from aluminum

The signal head itself is normally assembled by hand.

Polycarbonate signals are made similarly, but use an injection molding machine for the manufacture of the door, housing, visor, or lens parts. Plastic pellets are melted down in an injection machine. A screw then turns forcing the melted plastic into the mold. When the part cools it ejects and the sprues are trimmed off. Noticable marks from the screw injector on polycarbonate parts are on the back center of each section, and on the front center of most poly lenses.

TRAFFIC SIGNAL INSTALLATIONS

Traffic signal heads are installed in many different fashions. The three main installation practices, generally, are mast arms, span wire, or pedestal mount.

Mast arm signals involve a horizontal pipe suspended across the roadway, with either one or, less common, two, support poles. The signal heads are then rigidly attached to the pipe, although some older models tend to be suspended from them. Mast arms provide a more sleek look but also cost substantially more to install.

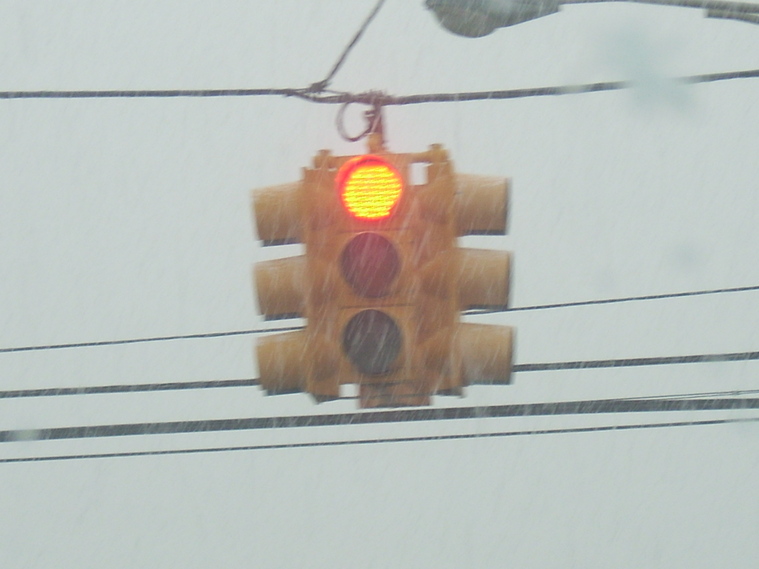

Span wires are arguably the most common installation of traffic signals. Signal heads are suspended from a metal wire using a hanger assembly and clamp. Electical wiring is then tightly strapped to the metal wire that the signals hang from.

Pedestal signals were used for vehicle signals long ago, but mostly are used nowadays for pedestrian signals. Pedestals are short, thin poles, usually only about 8 feet tall. A signal head, or group of two or more heads are fastened to a slip fitter that is installed on the top of the pedestal.

Mast arm signals involve a horizontal pipe suspended across the roadway, with either one or, less common, two, support poles. The signal heads are then rigidly attached to the pipe, although some older models tend to be suspended from them. Mast arms provide a more sleek look but also cost substantially more to install.

Span wires are arguably the most common installation of traffic signals. Signal heads are suspended from a metal wire using a hanger assembly and clamp. Electical wiring is then tightly strapped to the metal wire that the signals hang from.

Pedestal signals were used for vehicle signals long ago, but mostly are used nowadays for pedestrian signals. Pedestals are short, thin poles, usually only about 8 feet tall. A signal head, or group of two or more heads are fastened to a slip fitter that is installed on the top of the pedestal.